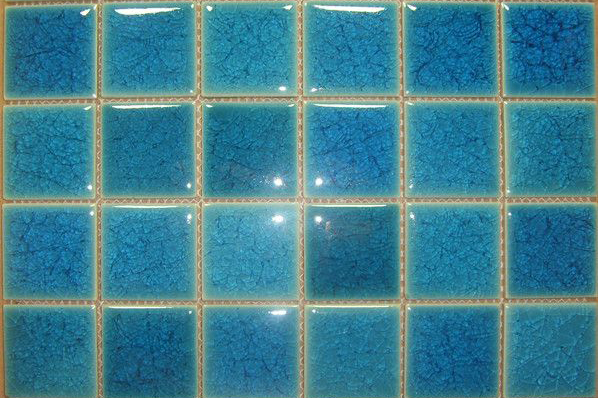

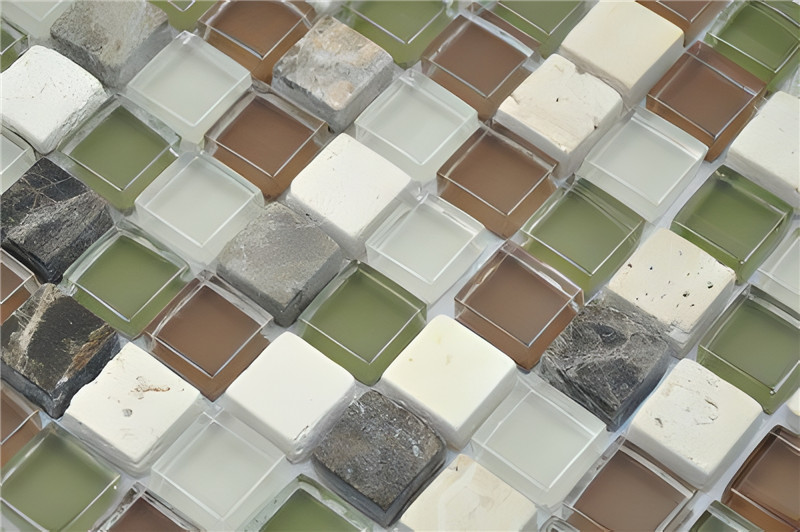

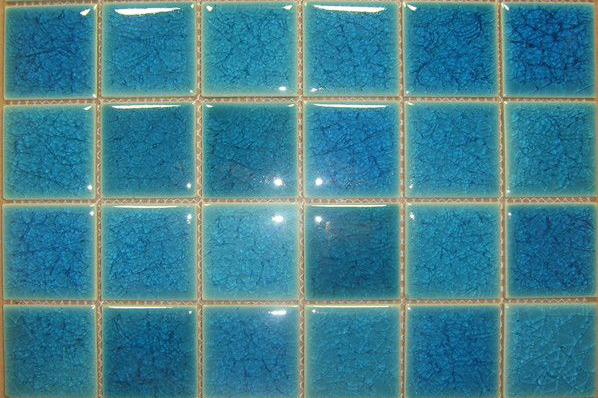

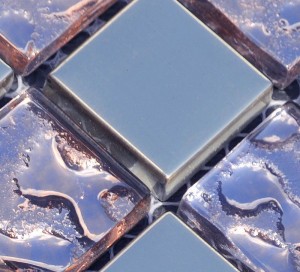

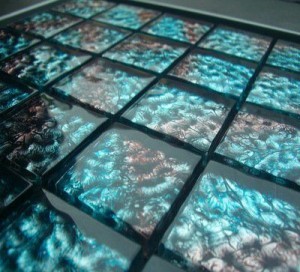

Colorful enamelled glass bathrooms and exterior walls are available

Product Description

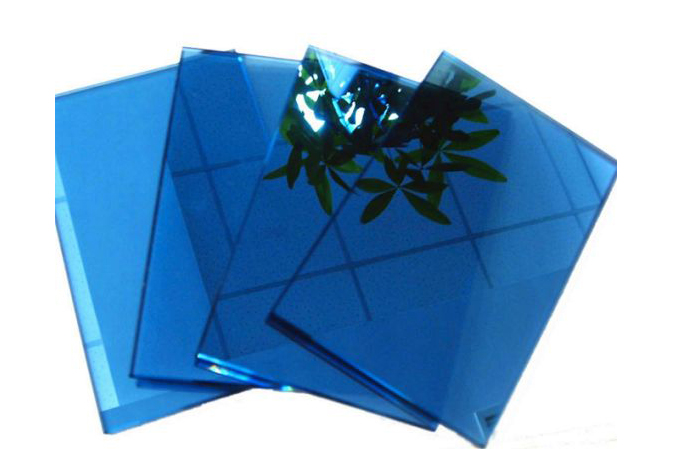

Enamelled glass refers to the glass surface cut in a certain size coated with a layer of color fusible glaze, heating to the glaze melt, so that the glaze layer and glass firmly together, through sintering, annealing or tempering processing process, the tempered enamel glass made has beautiful colors and patterns. It has good chemical stability and decorative, suitable for building exterior wall finishes.

The production of enamelled glass includes the production of colored glaze, glazing, drying, heating, quenching or annealing, cooling and other processes.

There are two basic materials in the production of glass glaze, base glaze and pigment, base glaze is the powder of fusible glass frit; Pigment is an inorganic coloring substance. It can be an inorganic compound or several inorganic compounds. It is made by grinding, mixing, sintering and grinding into powder in a certain ratio.

(1)Base Glaze

The role of the base glaze is to disperse the inorganic pigment highly, and melt on the surface of the glass substrate at a low temperature, and the substrate is integrated into a whole; When the base glaze is fused, the inorganic pigment with strong coloring ability will dye it into color glass, and the layer of glass and glass substrate are combined into a whole and become colorful glazed glass. The technical performance of the base glaze is required: the melting temperature is low, which can be melted on the surface of the glass substrate before softening; It has good chemical stability and luster, and does not produce chemical interaction with inorganic pigment, neither causes the color of inorganic pigment itself to change; The expansion coefficient is very close to the expansion coefficient of the glass substrate. When the temperature changes, the glaze does not crack and burn.

(2)Pigment

Pigment, it is a kind of metal oxides or compounds, can also be made by several metal oxides or compounds, according to a certain ratio of grinding, mixing, sintering, washing, filtering, drying, and grinding into fine powder. Various colors of pigment, the choice of metal oxide, no softening, the sintering temperature and sintering time is different from the pigment. The dispersion of pigment in use has a close relationship with its particle size, the smaller the particle, the greater the dispersion (the particle is generally less than 5 um).

Enamelling

1. Roll coating method Roll coating method is the principle of transfer roll printing technology, the thick colored glaze is coated on the surface of the glass substrate using a rubber roller.

2. Screen printing method The method is the transplantation of screen printing technology and modern textile technology, the use of screen printing press, the glaze slurry, coated on the glass substrate one or more kinds of glaze. Wire mesh is made of synthetic fiber or stainless steel wire.

3. Stamping method This method uses a flexible soft material carved into the scene pattern of the seal, the seal with a layer of colored glaze paste, and then printed on a clean glass substrate.

4. The sticker method is an extension and expansion of the screen printing method. It is to print complex scene patterns of various colors downstream on a special paper. When used, water is used as a binder, and it is pasted on a clean glass substrate, which is dried and then heated.

Dry

After glazing, the glaze layer must be dried for the next step. According to the glazing process and production scale, natural drying, chamber electric drying and continuous electric drying can be selected as the drying process.

Heating and cooling

enamelled glass equivalent heating and cooling according to the different production methods, the selected process and equipment:

1.Toughening method

The process of the toughening method is to transfer the glazed dry glass sheet into the toughening furnace and heat it to 670~715℃, and then quickly move it into the air shed for quenching.

2. Semi-tempering method

Semi-tempering method The process of this method is to transfer the glazed dry glass sheet into the heating furnace and heat it to a certain temperature, and then move it into the cooling chamber for controlled cooling. Heating annealing method It is the dry glass sheet after glazing into a continuous roller table heating cellar, in the kiln after preheating, heating, annealing, cooling and made of glazed glass. The maximum temperature in the kiln is 670~715℃, and then annealing and cooling are carried out according to a certain temperature regime.

Advantage

1.Mechanical properties

With good chemical stability and decorative, can be made according to the user's requirements or artistic design pattern.

2. Enhanced aesthetic effect rich color

Exquisite pattern, do not fade, do not fade, easy to clean.

Applied range

Interior finishes, foyers and stairwells of general buildings and exterior finishes of buildings; Shading and spacer walls, screens and other building components required by the building; Glazed glass partition oven door, stove top, countertop and superior furniture fittings; Glazed glass frame lamp shade, extinction shade, shade and other lighting accessories; Glazed glass lamp shade car glass edge, etc.

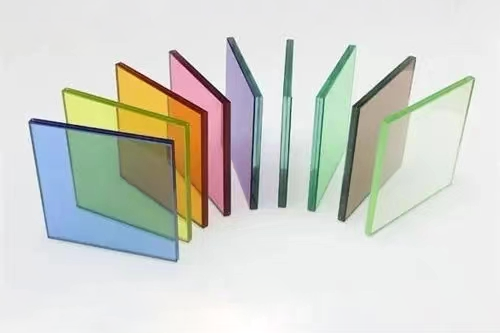

Color

Inorganic pigments commonly used for glass printing ink are as follows:

1. Red -- cadmium sulfide;

2. Yellow - lead chromate, cadmium sulfide, uranium salt;

3. Green - chromium oxide;

4. Blue - cobalt aluminate;

5. Brown - iron oxide;

6. White - calcium oxide, kaolin, etc.

7. Black - iridium oxide, manganese oxide and other mixtures;

Production Qualification

The company's products have passed China compulsory quality system CCC certification, Australia AS/NS2208:1996 certification, and Australia AS/NS4666:2012 certification. In addition to meet the national production standards, but also meet the overseas market quality requirements.