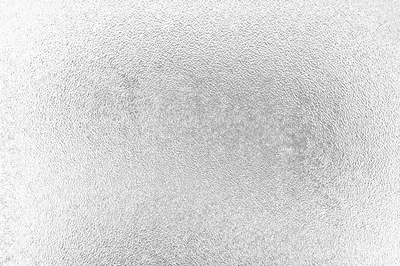

Patterned frosted glass for use in the bathroom

Product Description

With the rich material wealth of society, people require to be liberated from the "accumulation of things", and there is a unified overall beauty between various indoor objects. Interior environment design is a whole art, it should be space, form, color and the relationship between the virtual and real grasp, the combination of functional relations grasp, grasp the creation of artistic conception and the relationship with the surrounding environment coordination. Frosted glass came into being.

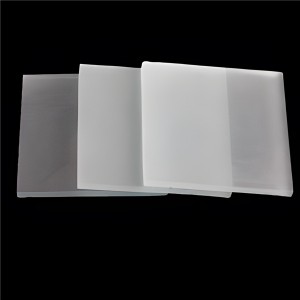

Frosted glass, also known as ground glass, dark glass is the use of ordinary plate glass by mechanical sandblasting, manual grinding or hydrofluoric acid dissolution method to treat the surface into a uniform surface of translucent glass. As a result of the rough surface, so that the light generated diffuse reflection, light transmittance without perspective, it can make the indoor light soft and not harsh. It is often used for doors, Windows and partitions of bathrooms, toilets and offices that require concealment.

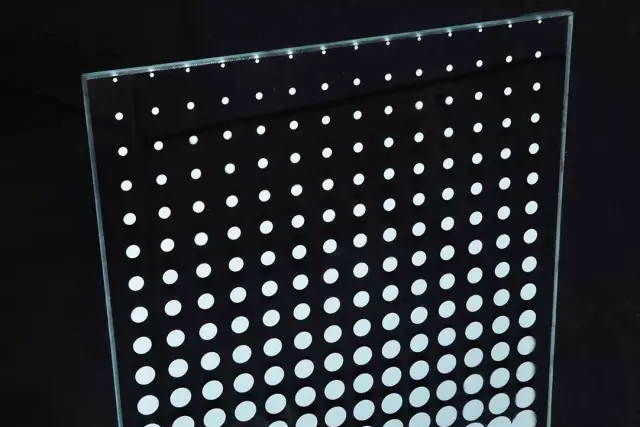

Sandblasting glass is a process of water mixed with emery, high pressure injection on the glass surface, so as to polish it. Including spray glass and sand carved glass, it is the automatic horizontal sandblasting machine or vertical sandblasting machine in the glass processing into a horizontal or intaglio pattern of glass products, can also add color in the pattern called "spray glass", or with the computer engraving machine, deep carving shallow engraving, the formation of brilliant, lifelike art. Frosted glass uses a high-tech process to cause erosion on the surface of flat glass, thus forming a translucent fog surface effect, with a hazy aesthetic feeling. In the decoration of the room, it is mainly used in the performance of the defined area but not closed place, such as between the dining room and the living room, can be made of sandblasted glass into a fine screen, so that life is more wonderful and emotional appeal.

Product Processing

Frosted glass is divided into single side frosted and double side frosted, which can be customized according to demand.

Advantage

1. Protect your privacy at home.

2. Doors and Windows with special requirements can be selected according to demand.

3. Frosted glass can be toughened, with good lighting, high strength, broken after the characteristics of no injury.

4. Sound insulation, heat insulation, fire prevention, anti-fog.

5. Transparent light, no perspective, colorful patterns.

Range of application

Frosted glass is mainly used in indoor partition, decoration, screen, bathroom, furniture, doors and Windows.

Notes

1.The distance between the spray gun and the glass should be proper.

2.The moving speed of the spray gun should be stable.

3.Open the sand to see whether it is uniform in time, if there is no sand or uneven sand, to check whether the nozzle is blocked or check whether the emery pipe is blocked and cleaned.

4.Through the backlight to observe whether the carved texture is uniform, uneven place should be trimmed.

5.After the completion of carving, wash the remaining sand with clean water first, remove the engraving paper, and then remove the remaining sand with clean water. It is necessary to pay attention here that the remaining sand must not be left on the glass surface, so as not to place the glass is emery and scratch the glass surface.

Production Qualification

The company's products have passed China compulsory quality system CCC certification, Australia AS/NS2208:1996 certification, and Australia AS/NS4666:2012 certification. In addition to meet the national production standards, but also meet the overseas market quality requirements.