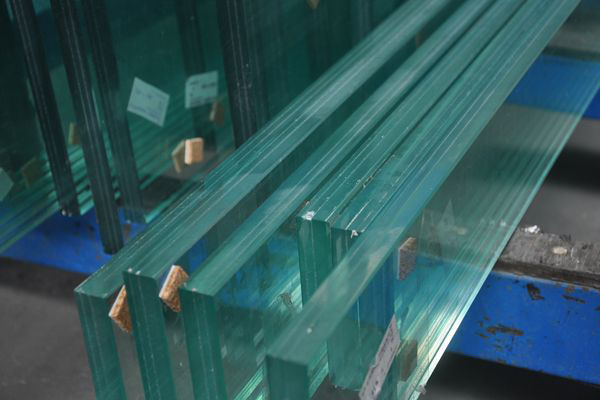

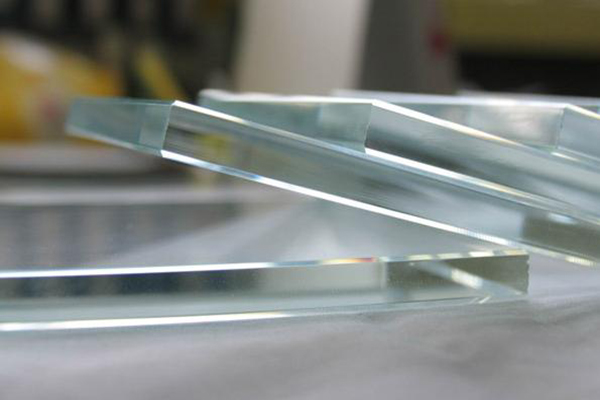

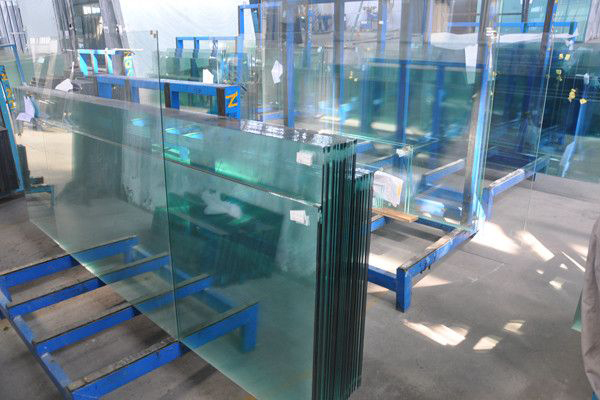

High safety tempered building glass heat soaked tempered glass

Heat soak test (HST)

Self-detonation of tempered glass

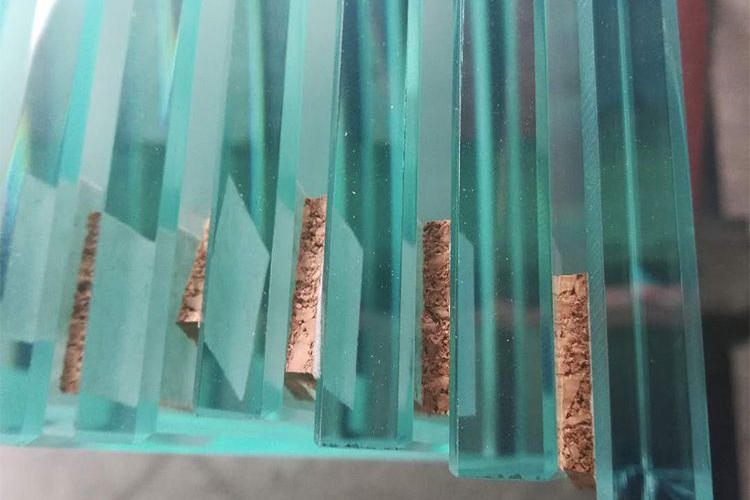

Tempered glass has an inherent defect of "self-detonation" - tempered glass in the absence of direct external action and automatically broken phenomenon. In the process of tempering processing, storage, transportation, installation, use, etc., tempering glass self-explosion can occur. Modern float glass production techniques cannot completely eliminate the presence of nickel sulfide (NiS) impurities, so the tempering self-detonation is inevitable, which is an inherent characteristic of tempered glass. At present, there is no standard of any country in the world to limit the self-detonation of toughened glass. According to the experience of China's glass industry, the self-detonation rate of ordinary toughened glass is about 3~5‰. In order to avoid the occurrence of self-explosion of toughened glass used in important projects and important places, heat soak test can be carried out first.

Heat soak test is also known as homogeneous treatment, commonly known as "detonation".The glass obtained is called hot dip glass. Heat soak test is to heat the tempered glass to 290℃±10℃ in the "homogenizing furnace", and hold it for a certain time, so that the nickel sulfide (NiS) in the tempered glass quickly complete the crystal phase transformation to accelerate its expansion process, so that the originally used after the tempered glass may explode artificially in advance in the factory "homogenizing furnace", Thus reducing the use of tempered glass after installation self-detonation,increased safety. After heat soak test, the self-detonation rate of tempered glass can be reduced to about one in 10,000, but heat soak test can not guarantee that the tempered glass absolutely does not occur self-detonation, but only reduces the occurrence of self-detonation, and actually solves the problem of self-detonation that has plagued all parties in the project. Therefore, heat soak test is the most effective way to solve the problem of self-detonation under the current technical conditions unanimously recognized in the world.

Advantages of heat soak tempered glass

Low self-detonation rate: according to statistics, the self-detonation rate of tempered glass with heat soak test strictly according to the process can be reduced from 0.3% to 0.01%, much lower than the self-detonation rate of ordinary tempered glass.

More safety and reduce the later maintenance and repair costs: because of the low self-detonation rate, reduce the accident caused by the self-detonation of tempered glass, and greatly reduce the cost of the tempered glass self-detonation to better protect the glass.