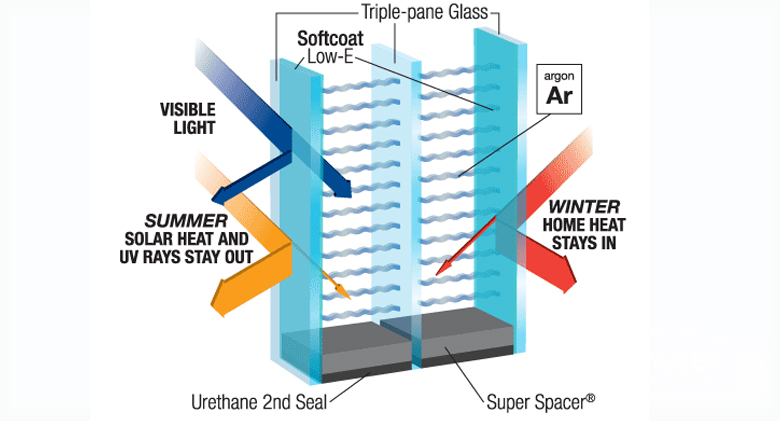

Insulating glass, also known as double glazing, has been known for its energy-saving effects for many years and plays a vital role in creating a comfortable indoor environment. When considering insulating glass, it is essential to understand the role of the gas inside the glass. At the end of the last century, some inert gases with higher density, smaller thermal conductivity and more stable performance (argon, krypton, xenon) were used to fill insulating glass to improve the insulation performance and energy saving effect of insulating glass.

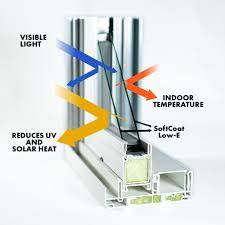

The research shows that the inert gas can reduce the heat conduction of insulating glass and reduce the glass U value. Compared with insulating glass filled with ordinary dry air, inert gas can improve the insulation performance of about 10%; In colder climates, insulating glass using argon can reduce energy consumption by up to 30%, while in warmer climates it can reduce energy consumption by up to 20%. In addition to improving thermal insulation performance and reducing heating and air conditioning costs in winter and summer, inert gases can make the inner surface of the glass closer to room temperature, which is not easy to dew and frost in winter, preventing condensation in the window. It also reduces the transmission of noise and adds a layer of sound insulation to the house or building. This feature is particularly effective for those who live in noisy environments or near busy roads.

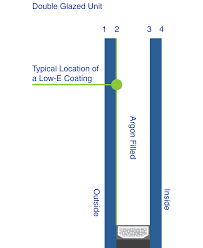

The results show that the insulating glass filled with inert gas has a certain influence on the shading coefficient Sc and the relative heat increase RHG. In addition, when using low-radiation LOW-E glass or coated glass, because the filled gas is an inert inert gas, the protective film layer can reduce the oxidation rate, thereby extending the service life of LOW-E insulating glass.

Now more and more owners like to install large floor-to-ceiling Windows, the area of insulating glass is getting larger and larger, easy to produce the uneven hollow layer, two pieces of glass by atmospheric pressure pressure inward suction, inert gas density is greater than air, for example, argon can reduce the internal and external pressure difference, maintain the pressure balance, can better resist the pressure of atmospheric pressure pressure. Reduce the glass explosion caused by the pressure difference to ensure the normal use of insulating glass. This can increase the strength of a large area of insulating glass, so that the middle will not collapse because of no support, and increase the wind pressure strength.

Why is argon mostly chosen for filling?

Filling argon is the most common and cost-effective: argon has the highest content in the air, accounting for about 1% of the air, it is relatively easy to extract, the price is more affordable, and it is suitable for home decoration doors and Windows. Argon is also an inert gas, safe and non-toxic, and does not react with other substances in the glass plate.

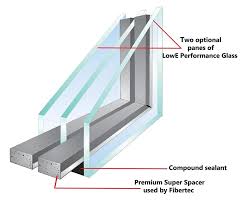

Krypton, xenon effect is better than argon, but the price is much more expensive, if you want a better insulation effect, it is better to spend money on improving Low-e glass, thickening the thickness of the glass and the thickness of the hollow layer, and adding warm edge strips. The hollow layer of insulating glass is generally 6A, 9A, 12A, 16A, 18A, 20A, etc., considering the thermal insulation and sound insulation performance of insulating glass, the thickness of the glass hollow layer is recommended to use 12mm and above, the effect will be better.

It must be noted that while argon has so many benefits, improper manufacture or installation can compromise its effectiveness. For example, if the glass plate is poorly sealed, the gas will inevitably escape, reducing the energy saving effect. Therefore, it is crucial to choose a reputable manufacturer to ensure the effectiveness of insulating glass.

Agsitech strictly follows the sealing steps, using butyl adhesive materials with particularly excellent air tightness and water tightness. It also takes into account good chemical and thermal stability, giving priority to ensuring the tightness of the glass. If the glass leaks inside, no amount of subsequent work will help. In addition, there is enough desiccant 3A molecular sieve in the aluminum spacer to absorb water vapor in the hollow cavity, keeping the gas dry, and good quality insulating glass will not produce fog and dew in a cold environment.

- Address: NO.3,613Road,Nansha Industrial Estate, Danzao Town Nanhai District, Foshan City, Guangdong Province,China

- Website: https://www.agsitech.com/

- Tel: +86 757 8660 0666

- Fax: +86 757 8660 0611

- Mailbox: info@agsitech.com

Post time: Jun-09-2023